Impact crusher, which can also be called impact breaker,impact pulverizer or impactor crusher, is a new type of high-efficiency crushing machine with the features of small size, simple structure, large crushing ratio, low energy consumption, large production capacity, uniform product granularity and selective crushing.

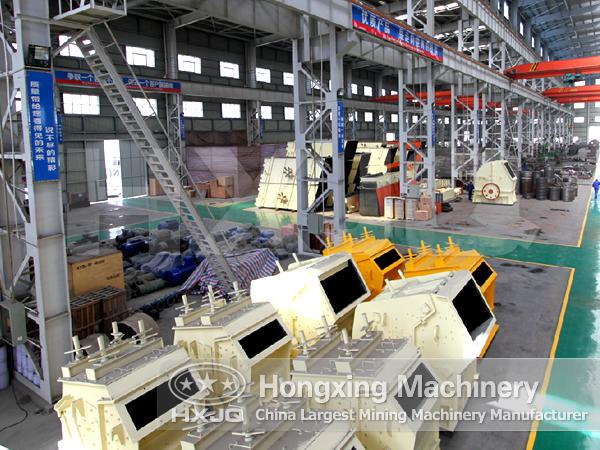

Mineral impact crusher is divided into single-rotor impact crusher and double-rotors impact crusher according to structural feature. Single-rotor impact crusher is divided into reversible turn and non-reversible turn type according to steering of rotor. There are impact stone crusher and mobile impact crusher.

Even though impact crushing machines of different manufacturers are different in model and mass, their working principle and structure are same. The impact crushing machine mainly consists of board hammer, impact plate, board hammer pedestal, rotor and feeding port.

Market price of impact breaker depends on model. We have many impact breakers with different models for you to choose from. Welcome new and old customers to choose!

When the impact crushing machine works, the motor drives the rotor which is installed with hammers at high speed. When the materials get into the area which the hammers affect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. And then the materials are rebounded from the impact liner to the area where the hammers function for re-crushing. The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the materials are crushed to the required size and then discharged from outlet of the impact stone crusher and mineral impact crusher.

| Model | Specifications (mm) |

Feed opening (mm) |

Max.feeding side length (mm) |

Capacity (t/h) |

Power (kw) |

Total weight (t) |

Dimensions (L×W×H) (mm) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 37-45 | 12 | 2330×1660×2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 45-55 | 15 | 2370×1700×2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 110 | 17.7 | 2680×2160×2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 100-180 | 132 | 22.4 | 2650×2460×2800 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 130-250 | 220 | 27 | 3180×2720×2620 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 300-550 | 315-400 | 50.6 | 3959×3564×3330 |

| PF-182 | Φ1800×2000 | 1260×2040 | 700 | 600-800 | 630-710 | 83.21 | 4400×3866×4009 |

To send inquiries, including feedback, requests for information, or questions, you may use our Feedback and Inquiries form below.

Fields marked by an asterisk (*) are required fields.