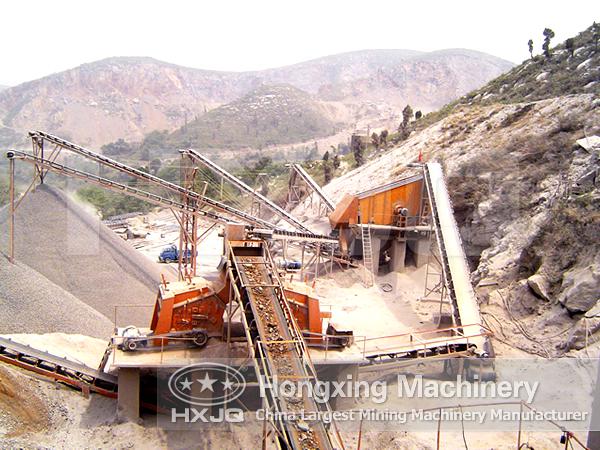

The belt conveyor manufactured by our company has the advantages of big conveying capacity, simple structure, convenient repair and standard parts, so it is widely used in the industries of mine, metallurgy and coal industry to convey loose materials and finished products. According to different technique requirements, the machine can convey material singly or form conveying system with other conveying equipment to meet different requirements of working line.

The working temperature of the materials to be processed should be below 50°C.

With the advantages of large conveying capacity, simple structure, easy maintenance, low cost and strong versatility, belt conveyors are widely applied in metallurgy, coal, transportation, water, electricity, chemistry as well as building material, electricity, light work, food, ports, ships and other departments.

The conveyor belt is mainly composed of two endpoint drums and a closed conveyor belt which is tightly set on the two drums. The rotatable drum known as the driving drum drives the converyor belt; the other one used for changing the direction of conveyor movement is called the deflector drum. The driving drum is driven by a motor through a speed reducer, and the conveyor belt is dragged by the frictional force between driving drum and conveyor. Materials are fed from the feeding end and fall on the rotated conveyor belt, and then they are transported to discharging end by the friction. The driving drum is generally mounted at the discharging end to increase traction to make it conducive to dragging.

| Belt width(mm) | Conveying length(m) Power(kw) |

Conveying speed(m/s) | Conveying amount(t/h) | ||

|

400 |

≤12

2.2

|

12-20

2.2-4

|

20-25

3-5.5

|

1.3-1.6 |

30-60 |

|

500 |

≤12

3

|

12-20

4-5.5

|

20-30

5.5-7.5

|

1.3-1.6 |

60-80 |

|

650 |

≤12

4

|

12-20

7.5

|

20-30

7.5-11

|

1.3-1.6 |

80-120 |

|

800 |

≤6

4

|

6-15

7.5

|

15-30

7.5-15

|

1.3-1.6 |

120-200 |

|

1000 |

≤10

5.5

|

10-20

7.5-15

|

20-40

11-30

|

1.3-2.0 |

200-320 |

|

1200 |

≤10

7.5

|

10-20

11-22

|

20-40

15-45

|

1.3-2.0 |

320-480 |

|

1400 |

≤10

11

|

10-20

18.5

|

20-40

22-55

|

1.3-2.0 |

588-1427 |

|

1600 |

≤10

15

|

10-20

22

|

20-40

30-75

|

1.3-2.0 |

700-1850 |

To send inquiries, including feedback, requests for information, or questions, you may use our Feedback and Inquiries form below.

Fields marked by an asterisk (*) are required fields.